The installation of overland high-voltage lines poses special challenges for people and equipment.

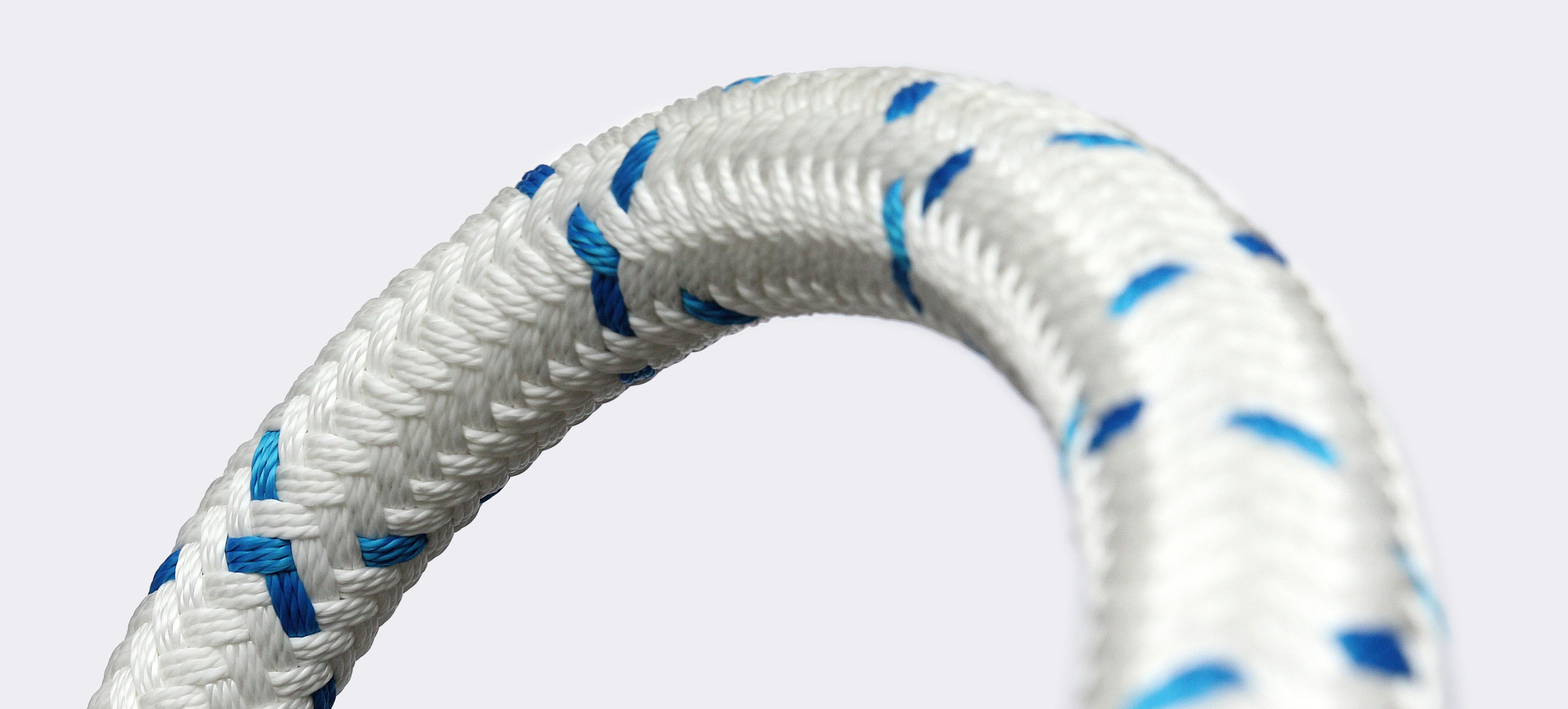

Complex structures are erected over long distances, often in difficult to access, rough or poorly developed terrain. When pulling the high-voltage lines, the required ropes are subjected to extreme loads. Our range of modern man-made/ synthetic fibre ropes enables you to make high-voltage cable installations significantly faster, easier and safer.

In earlier years, thin pilot lines were flown by helicopter from high-voltage pylon to high-voltage pylon. So-called intermediate ropes were pulled on these pilot lines by winch and the actual bull rope was then pulled by using this intermediate rope. Only then could the actual high-voltage line be pulled by the bull rope – like all other ropes before it, mostly wire ropes.

New and lighter fiber materials enable installation companies to save one or two of these intermediate steps. Light, highly-modular pilot lines made of Dyneema® or Texteel® are flown in by helicopter and the actual bull rope - often also made of Dyneema® or Texteel® can be pulled from mast to mast on these light ropes. This means that at least one, often two intermediate installation steps can be saved, and installation and machine times can be massively reduced. Man-made fiber ropes made of high-strength fibers such as polyester, BiPo or BiPo plus Polyester also help to pull ropes safely and economically.

Large rope lengths with the required end connections, on request directly on machine spools of the major cable winch manufacturers. For use in desert areas, our cable pull ropes are also available with integrated sand filters to protect the load-bearing core.

Our range therefore includes all the lines necessary for effective cable pull installations. We will be happy to assist you in choosing the right type of rope, provide information on correct rope dimensioning and help you to identify when it is ready to be discarded.

A special offer is our inspection and repair service, in which we inspect ropes returned to our manufacturing plants over their entire length, repair them and, if necessary, renew the over braiding/ braiding cover. This allows you to get the most out of your high-performance ropes and enables you to make sustainable, safe and long-term economic use of your investment.